Search

Recent comments

- ask claude...

1 hour 50 min ago - dumb blonde....

9 hours 13 min ago - unhealthy USA....

9 hours 46 min ago - it's time....

10 hours 8 min ago - pissing dick....

10 hours 27 min ago - landings.....

10 hours 38 min ago - sicko....

23 hours 27 min ago - brink...

23 hours 43 min ago - gigafactory.....

1 day 1 hour ago - military heat....

1 day 2 hours ago

Democracy Links

Member's Off-site Blogs

plan C...

The US government has demanded immediate clarification from BP over its commitment to pay for costs caused by the oil spill in the Gulf of Mexico.

The Obama administration said it wanted to be sure BP would honour commitments not to limit payments for damages to a US statutory cap of $75m (£50m).

Meanwhile, BP says oil dispersants applied at the source of the leak on Friday have begun to take effect.

Mississippi has become the third US state to have oil wash up on its coast.

http://news.bbc.co.uk/2/hi/americas/8684912.stm

-----------------------

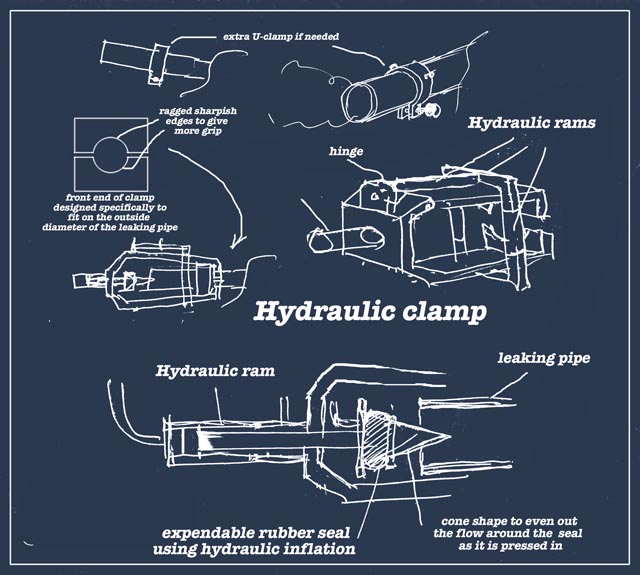

Meanwhile here is a second solution Gus... Plan C. (see first solution Gus)

For what it's worth I would propose here a variant on sewer pipes pugging devices. In one of my incarnation I got involved with inflatable devices such as these. Some were a couple of metres diameter. Simply it's like a giant champagne re-corker — you know the ones — that have a rubber ring (or two) that is (are) squashed up to expand by a lever pressing on the little lid at the top. The Sewer pluggers of course are much bigger and most use compressed air to expand the rubber ring or balloon.

Here, at 1500 metres below the surface, the technology is quite more complex due to the enormous pressures involved, that of the depth and that of the gushing oil.

Thus here, in the schema above, is a hydraulic clamping device to fit snug and hold very tight to the leaking pipe. Note the ragged edges for better pipe grip. Once the clamp is aligned (the conical shape at the front of the plug should help in the aligning) then secured, the next hydraulic device can slowly ram-in the plug. The conical shape at front is designed to even out the flow around the device as it is inserted — making sure it stays centred. As the rubber seal is pushed inside the pipe, still leaking, the rubber seal is then hydraulically expanded inside the pipe. The hydraulic ram should be built to withstand the pressure of the oil trying to gush out. The pressure on the rubber seal should be enough to stop the leak but not enough to blow up nor to crack the pipe...

a secondary clamp can be included if the engineers calculations show that the clamp may slip... But I don't think it would. I would allow four days for the making of such clamp and one for installation, noting that these are 24 hour days. Note there are other ways to design such a large clamp but this one above would be easy to build quickly...

Solution-Gus-One, that to bring the oil to the surface via a pipe with flexible joints and using high pressure steam to clear "crystals" that could defeat the cover box, would still be the preferred option as the oil could still be collected relatively free of sea water.

- By Gus Leonisky at 16 May 2010 - 3:10pm

- Gus Leonisky's blog

- Login or register to post comments

worse than it looks...

Scientists are finding enormous oil plumes in the deep waters of the Gulf of Mexico, including one as large as 10 miles long, 3 miles wide and 300 feet thick in spots. The discovery is fresh evidence that the leak from the broken undersea well could be substantially worse than estimates that the government and BP have given.

solution zee...

Oil giant BP says it is confident it will soon be able to stop oil from flowing into the Gulf of Mexico from a blown-out well.

The US government has now approved the use of dispersants under water near the source of the leak and BP says they are starting to work.

Engineers are also using underwater robots in an attempt to reinsert a tube surrounded by a stopper into the broken pipe.

They hope this will help them siphon the oil to the surface.

Doug Sutttles from BP says the operation is continuing and he is confident it will start working in the next few hours.

"We're in the process of setting up the riser insertion tube," he said.

"This is the method to contain the flow. This doesn't stop the flow but it contains the flow.

"We hope to have that tool inserted by some time late tonight. It's back on the seabed."

---------------------

Hopefully this will work....

the old pipe in the pipe trick...

Obviously, one has thought of the old "pipe-in-the-pipe-trick" but although simple in theory it still is complex as it could leak nonetheless, unless the fit was very smug (which would meen the fitting of a hydraulic ram to push it in — or say use a conical shape tube that would slowly lock in as it is pushed in). It appears that BP has managed to rig a temporary pipe to collect some of the oil and send it to the surface.

Note: The hydraulic ram at top and the inflatable "sewer plug" can also be used to connect pipe to pipe: in this case the "plug" has a hole/vent connected to a collector pipe

-----------------------

After two false starts, engineers successfully inserted the pipe outfitted with a tool called a riser insertion tube into the damaged line from which the majority of the oil is leaking.

“We inserted the tool again this morning, it’s working as planned, and we’re very slowly increasing the rate that’s coming from the riser,” Kent Wells, BP’s senior executive vice-president, said at a briefing in Houston on Sunday afternoon. “So we do have oil and gas coming to the ship now, we do have a flare burning off the gas, and we have the oil that’s coming to the ship going to our surge tank.”

-------------------------

their fit is not smug enough...

Meteorologists in the United States are warning of an unusually active hurricane season this summer, stirring concerns that just one severe tempest at sea early on could cripple ongoing operations by BP and the US government to plug the crippled oil well in the Gulf of Mexico and contain the already giant spill.

"All efforts on the shoreline and at sea, the booms and structures and rigs involved in clean-up and containment could stop working," said Ian MacDonald, a professor of oceanography at Florida State University. "If a storm comes into this situation it could vastly complicate everything."

Executives for BP said last night that a tube successfully inserted into the mouth of the well's riser pipe over the weekend was capturing roughly one fifth of that leak and delivering the oil and the gas to a tanker above. They expressed hope that the quantity of oil entering the pipe would increase in the coming days. While it represented a first bit of encouraging news, officials in Washington said the tube was "not a solution" to the problem.

---------------------

Thus so far they are collecting one fifth of the leak through a smaller pipe. Not good enough. The idea of a conical shaped smaller pipe (see drawing above) would be more effective. Meawhile let me put forward plan F for the leaks on the seafloor.

The idea is to place a funnel on top. Nothing new. But the funnel needs to be heavy enough and have a large enough footing. It could also need some loose "jointing compound" to seal it. It will also need anchors to secure it. The idea from beach unbrellas is not new and using a long pitch thread to spin the anchor as it is pushed through comes from double barrel car jacks devised at the beginning of the 20th century... Once the "funnel" is in place, a heavy "bell", with an inverted flexible seal inside it and a pipe back to the surface at the top, is lowered onto the funnel pipe. Note" the seal has to flexible enough to allow the fit but sturdy enough not to collapse under the pressure of the leak. The more pressure from the leak, the tighter the seal becomes.

For what it's worth...

fraudulent drilling?...

It is quite extraordinary, that in a mea culpa of sorts, the agency that oversees the US drilling regulations and issue of licences to drill admits it was weak and may have been at fault. The BP lawyers would rub their hands in glee. Sure there has been lapses of overseeing, but have they "contributed to the disaster"? Meanwhile, workers on the rig admitted that they were under pressure to perform and strike oil as fast as the could. They too "operated at the limit of safety".

In the same mea culpa drive, we could blame ourselves for demanding more and more oil to consume in our cars, in the manufacture of our plastics and other purposes. In previous centuries, it was whale-oil that provided fuel to light our lamps and served other purposes such as cosmetics — a demand driving whales to near extinction, when the hunt became "mechanised".

In this gulf oil disaster, one could also blame the manufacturer of the rig and that of the safety shut-down system which at this point is deemed to be faulty.

A negligeable risk, should never be left unattended. A succession of errors or that of small risks can cumulate into a major disaster. But in the end, the "final" mistake is the one that takes the project over the edge, because before it, there is always time to pull back, or slow down, knowing that we're driving too fast.

That there could have been fraudulent activity at the federal agency has to be investigated thus.

-------------------------------

Federal Agency Chief Admits Lapses in Gulf Oil Spill

By JOHN M. BRODER and LIZ ROBBINS

Interior Secretary Ken Salazar, facing Congress for the first time since the Deepwater Horizon oil well blowout in the Gulf of Mexico last month, said Tuesday that weaknesses at his agency’s Minerals Management Service might have contributed to the disaster.

“We need to clean up that house,” he told the Senate Energy and Natural Resources Committee, referring to the minerals service.

Mr. Salazar said that the majority of the agency’s 1,700 employees were honest and capable but that there remained “a few bad apples.” He said that anyone found guilty of negligence or corruption would be rooted out.

The Obama administration has already announced that it will separate the minerals service’s conflicting functions of promoting offshore oil operations and regulating their safety and environmental compliance. Mr. Salazar said further steps would be needed to give federal oil regulators more resources, independence and authority to police oil drilling operations.

The hearings came as scientists were carefully monitoring the currents in the Gulf of Mexico after warning that crude oil leaking from the blown well off the Louisiana coast was moving into an area where it could be swept toward the Florida Keys and the Atlantic Ocean within the next two weeks. The spread of oil could threaten coral reefs and hundreds of miles of additional shoreline.

The National Oceanic and Atmospheric Administration greatly expanded the fishing ban on Tuesday to contend with the spreading oil, with the prohibited area now covering 19 percent of the Gulf of Mexico under federal jurisdiction, increased from roughly 8 percent.

A graphic depiction of the seriousness of the leak and its threat to the environment was depicted in new video clips which Senator Bill Nelson, Democrat of Florida, posted on his Web site after urging BP to make it available. The footage depicts black, billowing clouds of oil furiously leaking from the ruptured well.

sludge tide...

VENICE, LA. -- A tide of sludgy oil has begun washing into the fringes of Louisiana's coastal marshes, officials said Tuesday, as BP continued to siphon some of the oil gushing from a damaged well on the gulf floor but remained days away from trying to cap the leak.

Interior Secretary Ken Salazar told Senate committees Tuesday that the oil company would attempt a "dynamic kill" of the oil well Saturday. That procedure involves pumping thick mud into the well in hopes of blocking the oil.

fix it or else....

from the BBC

Oil firm BP may be "pushed out of the way" if it fails to perform in the Gulf of Mexico oil disaster clean-up, a top US official has warned.

Interior Secretary Ken Salazar said the British company had missed "deadline after deadline" in its efforts to seal a blown-out oil well.

But he said BP had agreed to pay clean-up costs beyond the current US $75m (£52m) liability limit.

Mr Salazar is due to visit the disaster site on Monday with other officials.

The oil leak began more than a month ago, when a drilling rig operated on behalf of BP exploded, killing 11 people.

Millions of barrels of oil have spewed into the ocean since then from the well's ruptured riser pipe, 1,524m (5,000ft) beneath the surface

The spill has reached Louisiana and is threatening Florida and Cuba.

Limited options

"If we find they're not doing what they're supposed to be doing, we'll push them out of the way appropriately," Mr Salazar told reporters after visiting BP's US headquarters.

The BBC's Madeleine Morris in Washington says Mr Salazar's comment is the strongest language yet used by a US official towards BP.

---------------

see various solutions Gus on this site...

oil trouble over water...

Above is my next solution for diverting the leaks at sea floor level...

It's a job for boilermakers and ship builders. Note the pipe of the funnel can be blocked, especially for transport. The whole thing would float till presented on position at the surface. Ballast can then be added to make it sink. There are floating cranes that can lift more than 400 tonnes and if necessary USE TWO BLOODY CRANES... I've done it before... two twenty tonne capacity cranes used to lift 35 tonnes. and note too that the funnel does not have to be round. It could be a pyramidal shape for all I care... Meanwhile:

BP Halts ‘Top Kill’ Effort to Seal Leaking Oil WellBy CLIFFORD KRAUSS, JOHN M. BRODER and LIZ ROBBINS

HOUSTON — BP temporarily stopped pumping drilling fluid into its stricken oil well in the Gulf of Mexico late Wednesday night after engineers saw that too much of the fluid was escaping along with the leaking crude oil.

BP officials said engineers spent Thursday revising their plans, and that the company hoped to resume pumping by midnight.

“We have not yet stopped the flow so the operation has not achieved its objective,” Doug Suttles, the chief operating officer of BP said in an afternoon news conference from Robert, La.

Mr. Suttles said that “nothing has gone wrong or has been unanticipated,” but that engineers had only partially been able to overcome the upward pressure of the escaping oil and gas from the leaking well. He said that the pumping operation was stopped in order to assess its progress and that they were also restocking vessels with more drilling fluid, known as mud, before restarting the operation.

“The fact that it’s taken more than 24 hours is not a big surprise,” Mr. Suttles said. “Some of things we’ve done are taking longer than we thought.”

The news of another delay in capping the well came on a day of rapid-fire developments from Louisiana to Washington.

A report from government experts, who said that the flow of oil from the well, which has been gushing since an explosion and fire wrecked a drilling rig in late April, had been several times worse than the preliminary estimate by BP.

stop 'n' start...

By CLIFFORD KRAUSS

HOUSTON — BP’s renewed efforts at plugging the flow of oil from its runaway well in the Gulf of Mexico stalled again on Friday, as the company suspended pumping operations for the second time in two days before resuming the procedure Friday evening, according to a technician involved with the response effort.

In an operation known as a “junk shot,” BP engineers poured pieces of rubber, golf balls and other materials into the crippled blowout preventer, trying to clog the device that sits atop the wellhead. The maneuver was designed to work in conjunction with the continuing “top kill” operation, in which heavy drilling liquids are pumped into the well to counteract the pressure of the gushing oil.

The company suspended pumping operations at 2:30 a.m. Friday after two junk shot attempts, said the technician, who spoke on the condition of anonymity because he was not authorized to speak publicly about the efforts. They resumed the procedure at about 3:45 local time, after the nearly 12-hour interruption.

The suspension of the effort was not announced, and appeared to again contradict statements by company and government officials that suggested the top kill procedure was progressing Friday. Andrew Gowers, a BP spokesman, said he would not give “blow-by-blow commentaries.” He added: “The operation is by definition a series of phases of pumping mud and shooting bridging materials and junk and reading pressure gauges. It is going to keep going, perhaps 48 more hours.”

If the top kill and junk shots fail, BP officials planned to try again to place a containment vessel over the leak, which might allow them to capture the oil but would not stop the leak. A previous attempt failed.

-------------------

Gus: Another device to stop leaks in a pressurised (rough) pipe is the old "umbrella"... Imagine a series of say ten strong umbrella shaped seals joined together on a rod "in opposition" one facing-inwards, one facing outwards, one facing inwards, one facing out etc... like a watertight bottle brush, once opened up... The design of the set would make sure the pressure from the leak itself would force the umbrellas to open up and block the escape to a great extend... Of course these umbrellas to be made of interlocking steel plates and strong rubber joints — like the type used on conveyor belts.

oil and water mix...

From the NYT

...

Still uncertain are the fates of deep coral reefs that live in the gulf, as well as the condition of a unique cluster of bottom-dwelling organisms only nine miles from the damaged well. The ultimate impact the spill will have on commercially important fish like tuna and snapper is anyone’s guess.

As the week wore on, the Joye-Asper team found more and more evidence for the existence of the plumes.

The water samples they pulled up suggested that any oil in the plumes was highly diffuse — not even visible to the naked eye. But when several gallons of the water were forced through a fine filter, tiny black oil droplets appeared.

Even in that diffuse form, the plumes were having a drastic impact on the chemistry of the ocean, with dissolved oxygen levels plunging as each plume drifted through the sea.

...

------------------------

sad, but expected...

By CLIFFORD KRAUSS and LESLIE KAUFMAN

HOUSTON — BP said Saturday that its latest attempt to stop the gushing oil well in the Gulf of Mexico was unsuccessful, and the effort, known as a “top kill,” was being scrapped in favor of yet another maneuver to stem the flow spreading into the waters.

The announcement marked the latest setback in the attempt to plug the spill that is polluting gulf waters at an estimated rate of 12,000 to 19,000 barrels a day. This is already the largest spill in U.S. history.

Doug Suttles, BP’s chief operating officer, said the next step is called a “lower marine riser package cap” and involves sawing off the riser and placing a device atop it to capture the escaping oil. Equipment has already been deployed on land and on the sea bed, he said.

“We have made the decision to move on to the next option," Mr. Suttles said. “Repeated pumping, we don’t believe, will likely achieve success.”

The failure of the top kill procedure, which was thought to be the company’s best option for stopping the leak, was announced after about 30,000 barrels of mud was injected into the well and three attempts were made at what is termed the “junk shot,” a procedure that involves pumping odds and ends like plastic cubes, knotted rope, and golf balls into the blowout preventer, the five-story safety device atop the well.

Earlier in the day on Saturday, Mr. Suttles had said it was too soon to tell whether the top kill procedure was working, but had appeared doubtful that it was going to be the answer.

“I don’t think the amount of oil coming out has changed,” he said. If this latest attempt is unsuccessful, a relief well is the option experts say is most reliably going to stop the current catastrophe. But could take until August to drill a relief well.

-----------------------------------

Gus: I am not surprised, but sad... In my little corner of the world, assessing the odds — but not knowing all the factors involved — I had the feeling the odds were ten to one against a successful "top Kill". The odds of a large cap as illustrated above, would have more than 80 per cent chance of success. Looking at the flow from the deep see pictures, one could estimate the pressure from the oil and gas leak is at least double (4500 psi) than the water pressure at this depth (2250 psi if my calculations are correct — I could be wrong).

This is why I believe that only a SOLID cap with a collecting vent can do the job. The one designed above can be made pyramidal for ease of construction but when completed and settled at the bottom it should weigh more than 2,000 tonnes. Why not use an existing 5,000/10,000 tonnes old ship about to be scuttled somewhere, and cut the deck open so the top sides are roughly in one single plane. Plus bolt a vent pipe through the bottom. Then sink it upside down under cranes "supervision". Early on, the vent at top could be used to control the speed of descent via an air pocket inside the device. Would need the floating cranes (say six) to reduce the rate of descent while getting deeper (the air pocket would shrink).

The device has to cover a large area, thus reducing the possiblity of missing the target and could cover several secondary leaks in the vicinity. The next stage is to place a bell with a seal, on top of the vent to capture the oil back to the surface. As the leak is captured, the cover can be buried with more rocks, etc. At some point, above the surface, the normal separator of gas and oil should apply, and either product can be captured — or the gas can be burned till a more efficient system of capture is installed.

My view.

Plugging oil leak

If the oil pressure is 4500psi and the water pressure 2250psi would a conical cap which doubles the cross sectional area of the pipe mean that the oil pressure would be decreased to a manageable level? Just thinking about hydraulic principles.

Similarly using this conical principle, the pressure could be further managed by one of the previously proposed methods in your blog.

I like your sketches BTW.

the whole thing should work...

Thanks for your comment...

It could mean, I hope, that the oil would come to the surface in pipes at around 2000 psi, which is quite high pressure to manage, but would have to be "non-regulated" to avoid back-pressure back at the bottom on the "fragile" connection... The way to decrease the pressure at the top is to have bigger pipes at the top... twice the size pipe at the top would bring the pressure down to 1000 psi.

Lets not forget the high pressure steam (or hot oil?) being send down to keep the lid warm and stop the "ice" forming as the methane expands... the whole thing should work... It should work better than the precision enginneered BP solutions that were too smart for what I could see. On some media diagrams I saw some very stiff pipes coming down to the cap while these pipes should be flexible enough in sections, to allow a certain amount of drift and drag... But as mentioned I do not have all the information at hand and can only speculate, using stuff I think I already know about but may not be suitable for that specific problem... Hopefully the engineers at BP will cap all the leaks soon and the BP operators will find enough ships to collect the oil coming to the surface. By the third ship, the oil should not contain any sea water.

conflict of interest...

The judge who overturned deepwater drilling bans allowing BP to resume oil extraction in the Gulf of Mexico, had shares in Transocean and other firms in the industry, it was revealed today.

Yesterday, a Louisiana-based judge Martin Feldman ruled that Barack Obama's six-month drilling moratorium in the Gulf was unjustified because it assumed that all deepwater drilling was as dangerous as BP's.

The White House promised an immediate appeal.

Meanwhile environmental groups have said Feldman's ruling may have to be rescinded because of the possible conflict of interests.

Feldman's most recent financial disclosure forms show that he was paid dividends from his shares in Transocean, the firm that owned the Deepwater oil rig that exploded in April killing 11 oil workers, prompting America's worst environmental disaster.

The forms, which relate to the calendar year 2008, also show that he sold shares in Halliburton, which was also involved in the disaster.

Feldman's other interests included Ocean Energy, Quicksilver Resources, Prospect Energy, Peabody Energy, Pengrowth Energy Trust, Atlas Energy Resources, and Parker Drilling.

http://www.guardian.co.uk/environment/2010/jun/23/judge-drilling-ban-shares-oil

cracks in their hard hats...

By IAN URBINA

WASHINGTON — A confidential survey of workers on the Deepwater Horizon in the weeks before the oil rig exploded showed that many of them were concerned about safety practices and feared reprisals if they reported mistakes or other problems.

In the survey, commissioned by the rig’s owner, Transocean, workers said that company plans were not carried out properly and that they “often saw unsafe behaviors on the rig.”

Some workers also voiced concerns about poor equipment reliability, “which they believed was as a result of drilling priorities taking precedence over planned maintenance,” according to the survey, one of two Transocean reports obtained by The New York Times.

“At nine years old, Deepwater Horizon has never been in dry dock,” one worker told investigators. “We can only work around so much.”

“Run it, break it, fix it,” another worker said. “That’s how they work.”

According to a separate 112-page equipment assessment also commissioned by Transocean, many key components — including the blowout preventer rams and failsafe valves — had not been fully inspected since 2000, even though guidelines require its inspection every three to five years.

The report cited at least 26 components and systems on the rig that were in “bad” or “poor” condition.

A spokesman for Transocean, who confirmed the existence of the reports, wrote in an e-mail message that most of the 26 components on the rig found to be in poor condition were minor and that all elements of the blowout preventer had been inspected within the required time frame by its original manufacturer, Cameron. The spokesman, Lou Colasuonno, commenting on the 33-page report about workers’ safety concerns, noted that the Deepwater Horizon had seven consecutive years without a single lost-time incident or major environmental event.

The two reports are likely to broaden the discussion of blame for the April 20 explosion, which killed 11 workers and led to the gusher on the seafloor that has been polluting the Gulf of Mexico for months.

BP has been under the harshest glare for its role, but the Justice Department has said its criminal investigation of the disaster will look at the role of the many companies involved.

incoming weather...

picture — http://www.goes.noaa.gov/browsh.html

Experts are considering whether a possible tropical storm could disrupt work at the site of the BP oil spill.

If bad weather over the Caribbean strengthens and then moves to the site in the Gulf of Mexico, ships will have to be withdrawn.

It could mean no work on the relief well for up to two weeks.

A final piece of casing needs to be cemented in place at the bottom of the relief well before it can then drill into the damaged well.

Once the casing is in place, engineers could begin the last drilling within five to seven days and then "kill" the well with mud and cement.

There is a 50% chance that a weather pattern currently over the island of Hispaniola will turn into a cyclone by Friday, the National Hurricane Center says. It is currently moving west-northwest.

A reconnaissance flight is to be carried out on Thursday.

Adm Thad Allen, the US official in charge of the spill response, said the decision whether to order ships out of the area would be a "judgment call" based on how the storm developed.

Shell Oil has already begun to evacuate employees stationed out in the Gulf.

massaging the nuz...

http://www.washingtonpost.com/wp-dyn/content/gallery/2010/07/22/GA2010072203183.html?hpid=artslot

Can you spot the difference?

PHOTOS | Astute bloggers find an altered reality in certain BP images.This is not new

Many of WWI pictures were montages and even some were shot in the comfort of studios...